No products in the cart.

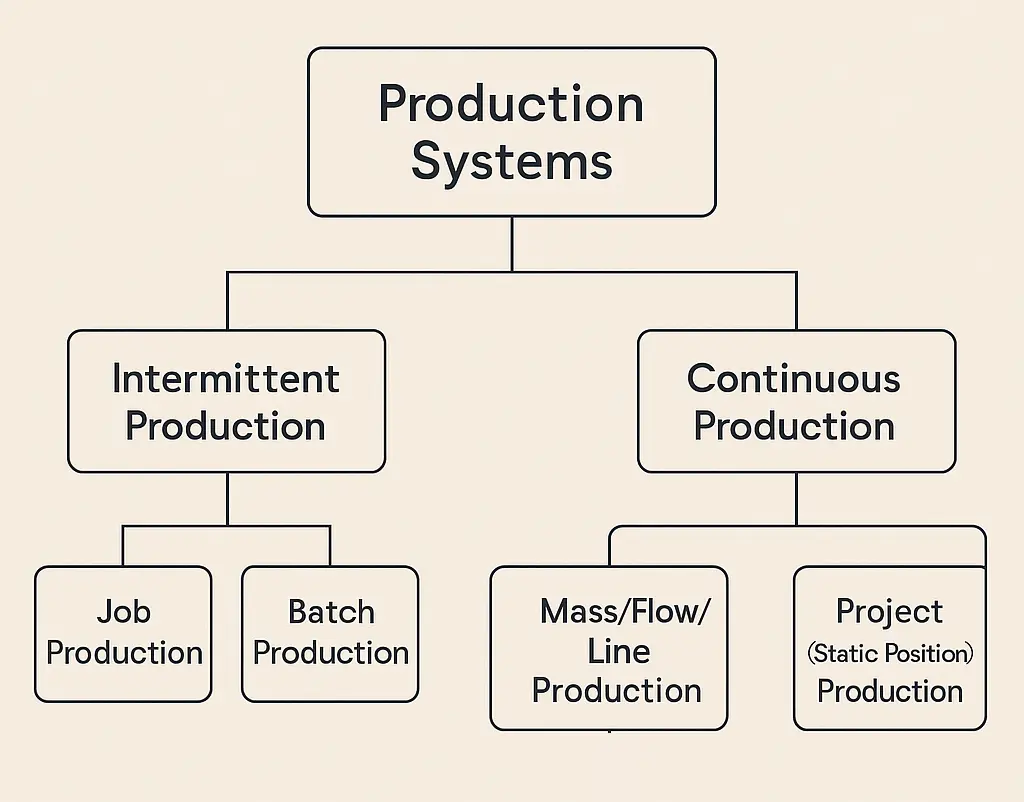

Understanding the classification of production systems is essential in Operations Management, as every organisation uses different methods to convert inputs into finished goods. The types of production systems commonly discussed include intermittent production, continuous production, and the project production system, each suited to specific industry needs.

These systems further include important methods such as job production, batch production, mass production, and process production, all of which play a crucial role in modern manufacturing practices. This blog explains each of these production systems in operations management with clear examples to help you understand how they function in real-world scenarios.

Table of Contents

Introduction to Classification of production systems

In Operations Management, a production system is the method by which an organisation converts inputs such as materials, labour, and machinery into finished goods or services. Every organisation chooses its production system based on the nature of its product, the level of variety required, customer demand patterns, and the volume of production. Broadly, production systems are classified into Intermittent Production, Continuous Production, and Project (Static-Position) Production. Each of these systems functions differently and is suited to different types of industries.

1) Intermittent Production Systems

Intermittent production systems are used when the flow of work is not continuous. Production begins only when an order is received, or when products are required in varying quantities. These systems are flexible and can handle a wide variety of products, making them suitable in industries where customer requirements frequently change. Two major forms of intermittent production are job production and batch production.

Job / Unit Production

Job production involves manufacturing a single, unique product at a time. Each job has its own specifications, requiring different processes, materials, and sequences of operations. There is no fixed routing because every order demands a different method. This type of production requires highly skilled workers and general-purpose machines capable of handling different kinds of tasks. Job production is suitable when personalisation, craftsmanship, and detailed attention are required.

Examples of Job Production:

Custom-made furniture is an appropriate example because each piece is designed and constructed according to the customer’s preferences. Wedding invitation designs also come under job production since each design is created based on specific names, colours, and themes. Special-purpose industrial machines, which are built according to the needs of a particular client or factory, represent another example of job or unit production.

Batch Production

Batch production refers to producing goods in groups or batches. All units within a batch follow the same production steps and are identical, but different batches may have different characteristics. Once one batch is completed, machines are adjusted or reset to produce the next batch. This system is ideal when demand is recurring but not high enough to require continuous production. Batch production maintains a balance between flexibility and efficiency.

Examples of Batch Production:

A bakery illustrates batch production well. Bread is baked in one batch, while cookies, pastries, or cakes are produced in another. Each batch requires a different mixture and setup. Similarly, pharmaceutical companies produce medicines in measured batches to ensure uniformity and quality. Garment manufacturers also produce clothing in batches, such as winter wear or festival collections, where each batch contains identical items.

2) Continuous Production Systems

Continuous production systems operate without interruption and are designed for producing very large quantities of standardised products. These systems depend heavily on specialised machinery, automation, and a fixed sequence of operations. Continuous production is ideal in industries where demand is high, and products are uniform.

Mass / Flow / Line Production

Mass production involves the continuous production of identical products using an assembly-line structure. The product moves from one workstation to another, with each station performing a specific task. Since the same steps are repeated for every unit, the entire system can be optimised for speed, efficiency, and low cost. Mass production reduces labour involvement and depends largely on machines and automated systems.

Examples of Mass Production:

Automobile manufacturing demonstrates mass production clearly. Cars move through assembly lines where welding, painting, fitting, and final inspection take place in a fixed order. Similarly, refrigerators and washing machines are produced in large quantities using standardised operations. Bottled beverages such as soft drinks also follow mass production, where filling, capping, labelling, and packaging are done continuously on dedicated machines.

Process / Continuous-Process Production

Process production is used to manufacture products that are homogeneous and cannot be easily separated into individual components. Materials flow continuously through processing equipment such as pipelines, reactors, furnaces, and mills. These systems run round the clock because stopping them can be technically difficult and economically wasteful. Process production requires advanced technology, strict monitoring, and high capital investment.

Examples of Process Production:

Oil refining is a common example because crude oil continuously flows through distillation towers and reactors to produce petrol, diesel, and other fuels. Cement manufacturing follows a similar continuous flow, with raw materials moving through crushers, rotary kilns, and grinders. Steel mills and chemical industries also use process production to maintain consistent quality and uninterrupted flow of materials.

3) Project (Static-Position) Production

Project production is used for large, complex, and unique outputs that cannot be moved during the production process. Instead of the product moving through a factory, labour, materials, and equipment are transported to the site where production takes place. Each project is handled in stages and demands careful scheduling, coordination, and supervision. This system is suitable when the final product is too large or fixed to be relocated.

Examples of Project Production:

Shipbuilding is a typical example. The ship remains at the dock while engineers, welders, materials, and machinery are brought to the location. Bridge construction is another example, where all construction activities are carried out at the site itself. Large infrastructure projects such as power plants or turnkey industrial installations also follow the project production system.

Conclusion

Each production system has a specific role depending on the type of product and the level of demand. Intermittent production offers flexibility and customization, continuous production emphasises efficiency and standardisation, and project production is used for large, unique, and stationary outputs. Understanding these systems helps organisations design suitable production processes that ensure high quality, cost efficiency, and timely delivery.

To check out more content of Operations Management You can use this Link